EUROPEAN NORMS

SUNGBOO protective gloves have been designed and manufactured in compliance with the requirements of the following European Standards. We declare with full responsibility that our gloves are safe Personal Protective Equipment of category I or II - as long as they are used in accordance with their intended use and properly selected. They are characterized by the highest quality of used materials and workmanship, thanks to which they ensure high comfort of work.

Pursuant to Regulation (EU) 2016/425 of the European Parliament and of the Council, three categories of risks have been defined against which Personal Protective Equipment (PPE) is to protect users:

- Category I: minimal risks

- Category II: hazards not included in categories I and III

- Category III: hazards that can have very serious consequences such as death or irreversible damage to health

EN ISO 21420:2020

PROTECTIVE GLOVES - GENERAL REQUIREMENTS AND TEST METHODS

This European standard replaces the previous standard EN 420: 2003. It defines the general requirements and relevant test procedures for glove design and construction, safety, comfort and performance, as well as labeling and manufacturer-provided information that applies to all protective gloves. The standard does not deal with the protective properties of gloves and should not be used separately, but only together with the relevant standards.

Security

A significant change in relation to the EN 420: 2003 standard is the assurance that the materials used in the production of protective gloves do not affect the user's health. The new EN ISO 21420 standard focuses on safety and introduces the following changes:

- new threshold for DMF (dimethylformamide) content for polyurethane (PU) coated gloves - a DMF level below 1000 mg / kg or 1000 ppm is required,

- enables compliance with REACH regulations on hazardous substances and substances of very high concern (registration, evaluation, authorization and restrictions on chemical substances),

- the level of polycyclic aromatic hydrocarbons (PAHs) for plastic materials in direct contact with the skin (only coated gloves) should be less than 1 mg / kg,

Electrostatic properties

The change also affects the electrostatic properties. The new standard EN 16350 sets the level of resistance to vertical resistance below 108 Ohm and introduces a new marking that must be placed on the gloves.

- For ATEX zones (from French: Atmosphères Explosibles - potentially explosive atmosphere), the electrostatic properties must be tested in accordance with EN 16350 (test method EN 1149-2). According to this standard, each glove material must have a low vertical resistance value of <108 ohms.

New pictogram to be attached to gloves.

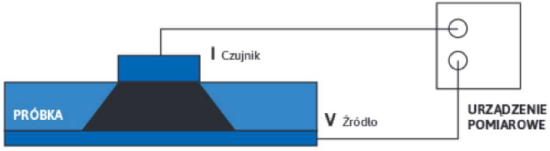

EN 1149-2 defines a test method that allows the measurement of vertical resistance, i.e. the material resistance expressed in ohms between two electrodes with a potential of 100 ± 5 V placed on opposite surfaces of the test sample, at a temperature of 23C and a relative humidity of 25%.

- For other electrostatic properties, the test method EN 1149-1 or EN 1149-3 must be used. No pictogram.

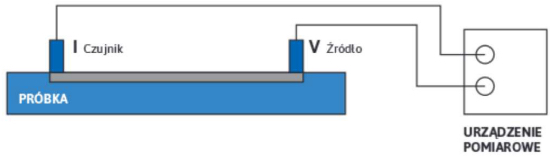

EN 1149-1 defines a test method that measures surface resistivity (Ω), that is, the resistance in ohms along the surface of a material between two specified electrodes (placed on the sample under test) with a potential of 100 ± 5 V.

EN 1149-3 defines a test method to measure the charge half life. T50 (s) is the time that must elapse before 50% of the charge on the material, as a result of being applied to it, has disappeared.

Glove sizes

The changes also apply to the size of the gloves. The new EN ISO 21420 standard requires that you define your own size systems, which must correspond to the size of the glove user's hand (length and circumference of the hand):

- in the case of a size, the length of the glove should be longer than the length of the hand

- this also applies to the circumference of the glove and the circumference of the hand

- size range

At the moment, the size range is from 4 to 13. The standard allows the possibility of adding full sizes or halves by extrapolation.

Marking

- Manufacturers are required to mark the identification of the batch of the product, such as the batch number or production date (at least month and year) - or use-by date (if applicable).

- The standard requires that the instructions for washing gloves be included in the instructions for use and, if applicable, whether the glove was tested before or after washing.

- The declaration of conformity must also be readily available for each product, for example at a website address.

Note: Valid EU certifications based on EN 420 are still valid.

EN 420: 2003 (REPLACED BY EN ISO 21420: 2020)

PROTECTIVE GLOVES - GENERAL REQUIREMENTS AND TEST METHODS

This European standard is a general standard referred to in the relevant European standards relating to or applicable to protective gloves. This standard should not be used in isolation, but only in conjunction with the relevant subject standard. It sets out general requirements and relevant test procedures for glove design and construction, water resistance of glove materials, harmlessness, comfort and performance, labeling and information provided by the manufacturer, which are applicable to all protective gloves.

An important element of the EN 420 standard is the correct dimensioning of protective gloves, in accordance with the table below:

| Glove size | Hand circumference [mm] | Hand length | Minimum glove length |

|---|---|---|---|

| 6 | 152 | 160 | 220 |

| 7 | 178 | 171 | 230 |

| 8 | 203 | 182 | 240 |

| 9 | 229 | 192 | 250 |

| 10 | 254 | 204 | 260 |

| 11 | 279 | 215 | 270 |

In addition, it is recommended that the protective gloves provide as much dexterity as possible, taking into account their intended use. Dexterity depends on many factors, e.g. material thickness, flexibility, deformability. The EN 420: 2003 standard specifies in detail the marking of protective gloves.

The marking should contain the following information:

- name, trade mark or other data identifying the manufacturer or his authorized representative;

- marking of the glove (trade name or code allowing the user to clearly identify the product with its manufacturer / authorized representative);

- size designation;

- if necessary, marking the expiry date - if the performance of the glove can be significantly lowered by aging;

- if the glove complies with one or more of the relevant European standards - graphic symbols corresponding to the standards.

EN 388: 2003 (REPLACED BY EN 388: 2016)

PROTECTIVE GLOVES AGAINST MECHANICAL RISKS

This standard specifies the requirements, test methods, marking and information to be provided for gloves that protect against the mechanical hazards of abrasion, cut, tear and puncture. This standard is only applicable in conjunction with EN 420.

Gloves protecting against mechanical hazards shall have a performance level of 1 or higher for at least one of the above-mentioned properties (abrasion resistance, cut resistance, tear resistance and puncture resistance) classified under the minimum requirements for each level in the table below.

| Research | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Abrasion resistance (number of cycles) | 100 | 500 | 2000 | 8000 | - |

| Cut resistance (index) | 1,2 | 2,5 | 5 | 10 | 20 |

| Tear strength (N) | 10 | 25 | 50 | 75 | - |

| Puncture resistance (N) | 20 | 60 | 100 | 150 | - |

Professional protective gloves offered by SUNGBOO Sp. o.o. are subjected to laboratory tests carried out in independent research laboratories, which determine their physical properties.

The test results are presented as an overprint on the dorsal part of the glove or as information printed on the label and are presented in the form of a pictogram. The following exemplary pictogram, presented below, informs us that a given protective glove has the highest level of abrasion resistance (4), the lowest level of cut resistance (1), the average level of tear resistance (2) and the lowest level of resistance to abrasion. piercing (1).

The range of possible outcomes (resistance) to the listed mechanical risks is as follows:

| Resilient to | Values |

|---|---|

| Abrasion | 0-4 |

| Intersection | 0-5 |

| Tear | 0-4 |

| Puncture | 0-4 |

All the above-mentioned mechanical risks are significant for the product, customers and users. Different test results, and therefore different levels of mechanical resistance, suggest the need to properly select individual types of protective gloves for different types of work. For example, work with a risk of injury requires the use of cut-resistant gloves, i.e. gloves that are highly cut resistant. In order to test this parameter, in accordance with the EN 388: 2003 standard, a test called Coupe test is carried out, which consists in moving the knife blade with a pressure of 5N forwards and backwards, and observing after how many cutting cycles the glove's knitted sample is cut.

EN 388:2016

PROTECTIVE GLOVES AGAINST MECHANICAL RISKS

This standard specifies the requirements, test methods, marking and information to be provided for gloves that protect against the mechanical hazards of abrasion, cutting, tearing, puncturing and, if applicable, impact. This standard is intended to be used in conjunction with EN 420.

Due to the fact that the PPE market has developed impressively and many products have (seemingly) similar levels of protection in accordance with the EN388: 2003 standard, there was a need to clarify the mechanical parameters of gloves. It was allowed by the revised EN 388: 2016 standard.

This is especially important for cut protection gloves. The coupe test that we write about in the EN 388: 2003 standard has been refined here in accordance with the ISO 13997 method, also known as the TDM-100 method. This methodology uses a different tool during testing, and it is particularly important to control the sharpness of the tool cutting the material sample.

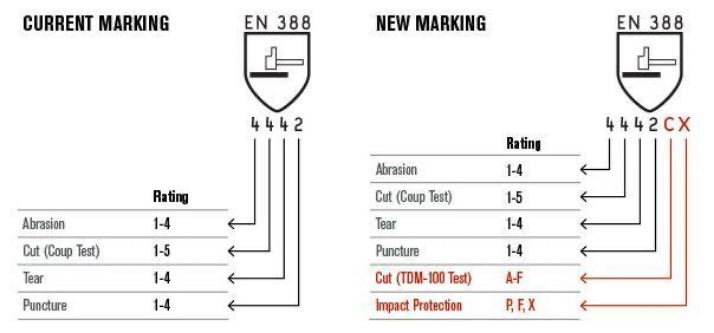

A fifth character has been added to the pictogram, i.e. a letter from A to F, which indicates cut resistance. Digital marking of cut resistance - as a result of the "old" Coupe, the test may also appear on the pictogram and will be an additional reference point. Additionally, the abrasion resistance test is performed with a new type of sandpaper (Klingspor PL31B 180), which is more repeatable. So the test result is more precise than before.

In addition, gloves that are designed to protect against impacts are tested for their resistance to impacts ("impact protection") in accordance with EN 13594: 2015. If the test is positive, it is identified by the letter P, if it is negative by the letter F, or if it is not tested by the letter X.

The pictogram, which is a bit more extensive, informs us about the test results. The diagram below shows us the way of marking protective gloves according to the currently valid standard EN 388: 2003 (in the figure as "current marking"), and in accordance with the new standard EN 388: 2016 (in the figure as "new marking"), which is already coming into use and awareness of all professional manufacturers, buyers and users of protective gloves.